During the late ’80s, APQP programs were in use by major players in the automotive industry. General Motors, Ford, and Chrysler all had an APQP deployment and saw the need to come together to create a common core of product quality-planning principles for suppliers. Because supply chains are important in automotive manufacturing, the intent was to make sure supplier partners met customer quality requirements for each component supplied. Guidelines were established in the early ’90s to ensure APQP protocols were followed in a standardized format. Since then, APQP has gained momentum and has sparked interest among manufacturers in many industries.

What does mean APQP?

APQP stands for Advanced Product Quality Planning.

In the manufacturing industry, as the complexity of a product increases—for example, a car is made of 30,000 parts including the smallest parts like screws, nuts, and bolts and the complete parts like Engine block, Transmission parts, and Clutch parts —so does the probability of error in the product lifecycle as work transitions downstream through the process chain in design, manufacturing, quality, supply chain, and another internal & external teams.

This is especially true for new products and new processes.

APQP is a set of standard procedures that documents the ability to produce a capable part with a reliable and repeatable process through a mutual understanding of the requirements and thorough risk assessment.

APQP is part of the five Core Tools (IATF 16949-compliant) for effective quality management with PPAP, FMEA, MSA, and SPC being the other core tools.

When is APQP necessary?

APQP is typically used for New Product Introductions (NPIs) when the OEM and suppliers are developing a new product and process together or when revising product or process changes after release.

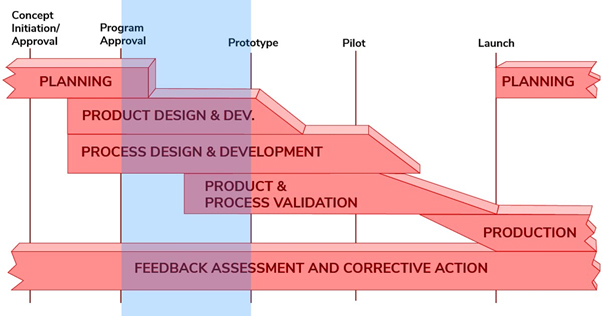

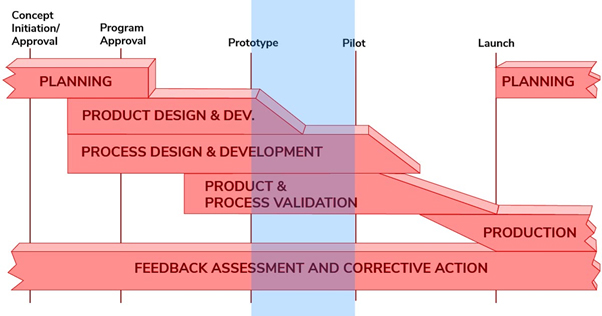

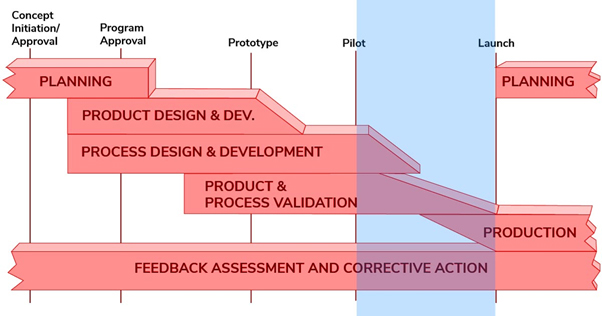

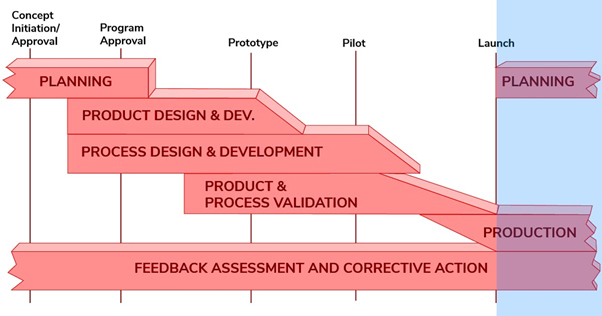

5 Phases of APQP

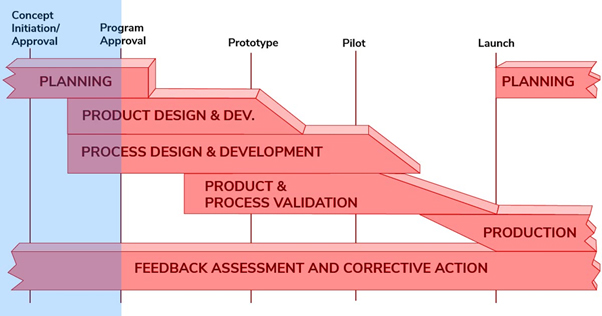

According to the American Society for Quality, Automotive Division, APQP is a structured process that includes critical tasks from concept approval through production. The aim is to create a product quality plan for developing and manufacturing products that meet customer requirements.

This planning uses a five-phase process:

1. Product Planning and Quality Program Definition

2. Product Design and Development

3. Process Design and Development

4. Validation of Product and Process

5. Production Launch, Assessment, and Improvement

APQP Phase 1: Planning and Program Definition

Phase 1 is all about understanding the customer requirements and expectations

When customer demands require the introduction of a new product or an overhaul of an existing one, preliminary planning becomes front and center, even before discussions of product design or redesign. In this APQP phase, planning is directed at understanding the customer’s needs and product expectations.

Planning activities include gathering necessary data to define what the customer wants and then using the information to hash out product characteristics. The quality program needed to create the product as specified can then be defined. The output of this work includes product design, reliability, and quality goals.

APQP Phase 2: Product Design and Development

Phase 2 verifies design feasibility and compliance

Completing product design is the focus of this phase. This is also where a product feasibility assessment comes into play.

Resulting outcomes from work in this phase include:

- Completed design review and verification

- Defined material specifications and equipment requirements

- Completed design failure mode and effect analysis to assess failure probabilities

- Established control plans for product prototype creation

APQP Phase 3: Designing and Developing the Process for Product Manufacture

Phase 3 verifies the manufacturing capability and measurement methods.

This phase focuses on planning the manufacturing process that will produce the new or improved product. The goal is to design and develop the production process while keeping product specifications, product quality, and production costs in mind. The process must be able to produce the quantities needed to meet expected consumer demand while maintaining efficiency.

Examples of outcomes in this phase include:

- A completed process flow configuration

- A completed process failure mode and effect analysis to identify and deal with risks

- Operational process quality specifications

- Product finishing and packaging requirements

APQP Phase 4: Validating the Process and the Product

Phase 4 validates the complete manufacturing process and final product.

This is the test phase for validating the manufacturing process and the final product.

Steps in this phase include:

- Confirming capability and reliability of the manufacturing process and product quality acceptance criteria.

- Performing production trial runs

- Testing product output to confirm the effectiveness of the deployed manufacturing approach

- Reconciling needed adjustments before moving to the next phase

APQP Phase 5: Launch, Assessments, and Continual Improvement

Phase 5 closes the feedback loop.

The full-scale production launch occurs in this phase, with emphasis on evaluating and improving processes. Mainstays in this phase include reducing process variations, identifying issues, and starting corrective actions to support continual improvement, as well as collecting and assessing customer feedback and data related to process efficiency and quality planning effectiveness.

Steps in this phase include:

- An improved manufacturing process through a reduction in process variations

- Improved quality of product delivery and customer service

- Improved customer satisfaction

APQP provides a structure for planning, defining, and completing necessary activities to produce products that are on target for customer needs and expectations. The program requires the use of standard quality tools, such as FMEA, SPC, PPAP, and comprehensive control plans for effectiveness.

For manufacturers, the incentive for using an APQP is the potential to achieve a successful product launch in which product and process risks are minimized and competitiveness is improved.

Avoiding Common Obstacles and Barriers

A clear view of how to productively implement APQP, and efficient training for implementation, are some of the best practices to fight the potential barriers and obstacles that are at times found in APQP. Another sort of protection against potential APQP issues is to possess a transparent understanding of the potential obstacles your organization might face. The following points are just a short instance of the tools, resources, and preparations your organization can use to reduce the propensity of APQP problems:

- An understanding of the APQP Key Elements

- A thorough understanding of the APQP Planning methods available

- APQP software designed to fit your company’s unique needs