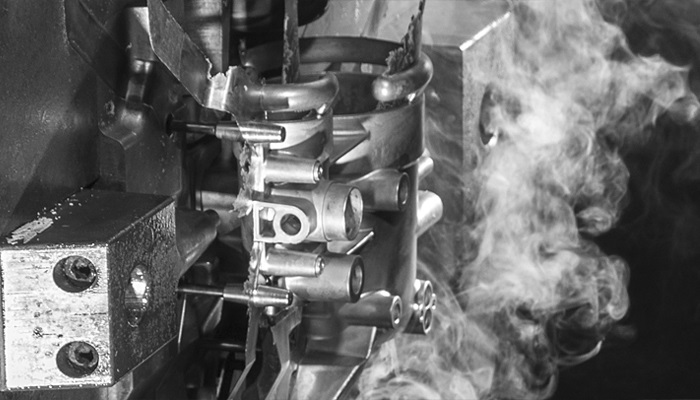

Aluminium Die Casting

The entire Aluminium Die Casting process of manufacturing takes place in a well equipped facility with the latest HPDC machined like Buhler , Zitai , Yizumi , Chit-Shun Etc

The largest casting that is presently produced in our facility is about 2.2 Kgs . Our closed loop and real time control die casting machines provide for highly repeatable process with reduced casting rejections and are the most preferred equipment for some of our customers producing safety critical parts for the auto industry.

A Central melting Tower furnace of 500kg/hr capacity along with a couple of BT furnaces of 500Kg capacity provide for molten metal to each of the Electric holding furnaces near the die casting machines.

Post die casting operations like fettling and trimming are carried out by semi-automatic machines. Drilling is carried out a conventional machines using special fixtures to keep costs low.

surface finishing operations like shot blasting and vibro finishing operations like shot blasting and vibro finishing are carried out in-house along with vacuum impregnation to supply pressure tight castings.

Followed by the Die casting and machining , Some the parts are getting chromating as well as powder coating as per customer requirements.

Using Hot chamber and Cold chamber Die-Cast technologies, along with standard and multi-slide tooling systems. Each of the alloys has unique Chemical and mechanical properties physical to meet out your specific application. We have a team of experts who will assist you to pick the right material to manufacture your complex geometry components.

We are specialized in manufacturing and supplying of Aluminum Casted parts in various process routes,

- High-Pressure Die Casting

- Low-Pressure Die Casting

- Gravity Die Casting

- Sand Casting

We make parts from few grams to large precision components in a broad range of

- Aluminum

- Zinc

Aluminum Alloy Characteristics

Aluminum’s strength, corrosion resistance, and heat-dissipating properties offer mechanical designers significant advantages. And our proprietary Thin Wall Aluminum Technology has made aluminum die casting an option for even more applications.

Advantages of Aluminum Die Casting

Various grade of Aluminum Alloys

High-Pressure Die Casting

A380 , A383 , A413, A360 , ADC1 , ADC 1Z

Low-Pressure Die Casting

A356, A413, AC2A, AC2B, AC4C, AC4A.

Gravity Die Casting

A356, A413, AC2A, AC2B, LM25, AC4A, Al-Si9Cu3.

Squeeze Die Casting

A380, A383.

Sand Casting

A356, A413, AC46200, AC2A.

Zinc

Zamak3, Zamak5, Zamak7

Magnesium

AZ91D, AM50A, AM60A

High Pressure Die Casting

Low Pressure Die Casting

Low-pressure die casting is a method of production that uses pressure – rather than gravity – to fill molds with molten metal such as aluminum and magnesium. In this process, the holding furnace is located below the cast and the liquid metal is forced upwards through a riser tube and into the cavity

Gravity Die Casting

Sand Casting

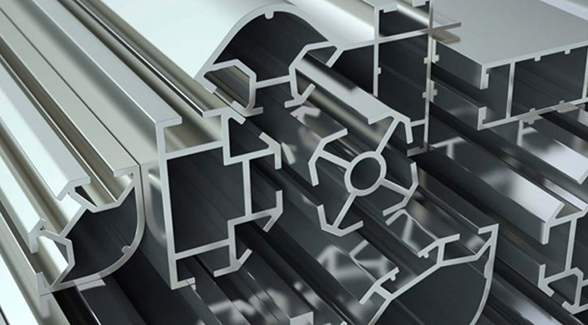

Extrusion

| IS India(NEW) | (BS)U.K or I.S.(OLD) | (AA) U.S.A |

(AICAN) Canada |

DIN Dermany |

ASTM | (JIS) Japan |

(AFNOR) France |

Russia |

|---|---|---|---|---|---|---|---|---|

| 19500 | E1B | 1050 or.1060 | IS | AI 99.5 | 99.6A | AI-1 | A-5 | – |

| 19000 | E1C | 1100 | 2S | AI 99.0 | 99.0A | AI-3 | A-4 | A-2 |

| 19501 | E1E | EC | CISDIA | E-AI99.5 | EC | AI-1 | – | – |

| 63401 | E91E | 6101 | D50S | E-AI-Mg.Si.O.5 | GS 10B | – | – | – |

| – | NE-3 | 3103 | 3S | AI Mn | – | – | 3103 | – |

| 52000 | NE-4 | 5052 | M57S | AIMg2 | GR 20A | A2-SI | A-G3 | AM |

| 53000 | NE5 | 5086 | 54S | AiMg3.5 | GM 40A | – | – | – |

| 63400 | HE-9 | 6063 | 50S | AiMg Si0.5 | GS 10A | A2-S5 | A-SG> | – |

| 24345 | HE-15 | 2014 | B26S | AI-Cu-Si | – | – | – | – |

Temper Designation Table

| INDIA or U.K | U.S.A or CANADA | ISO TEMPER | Description of designation |

|---|---|---|---|

| O | O | O | Annealed |

| M | F | F | As fabricated, as manufactured, or as cast |

| – | T3 | TD | Solution heat-treated and cold worked |

| W | T4 | TB | Solution heat-treated, naturally aged, and amenable to artificial ageing |

| P | T5 | TE | Artifically aged or precipitation heat-treated |

| WP | T6 | Tf | Solution heat-treated & Precipitation heat-treated |

| H-21 H-1 | H2A H1 | Strain hardened to the specified strength | |

| H-22 H-32 | H2B H3B | 1/4 Harf Stabilized | |

| H-24 H-34 | H2D H3D | 1/2 Harf Stabilized | |

| H-26 H-36 | H2F H3F | 3/4 Harf Stabilized | |

| H-28 H-38 | H2H H3H | Fully hard, stabilized |