Our Blog

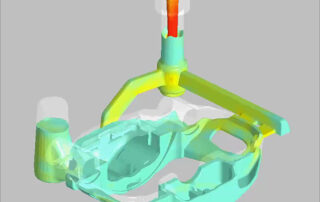

How Important Mould Flow Simulation in Iron Casting Parts

One of our customers from North America makes Steering systems and Brake systems for major auto OEMs. They have a new Hybrid model, which required High-Quality standards, such as NSD level casting (Non-Significant defect) and Good mechanical properties, they came to use it to find the solution and make the […]

Why is APQP is Essential for the Manufacturing Industries

During the late ’80s, APQP programs were in use by major players in the automotive industry. General Motors, Ford, and Chrysler all had an APQP deployment and saw the need to come together to create a common core of product quality-planning principles for suppliers. Because supply chains are important in […]

The Hidden Fact of SPC

Statistical process control (SPC) is defined as the use of statistical techniques to control a process or production method. SPC tools and procedures can help you monitor process behavior, discover issues in internal systems, and find solutions for production issues.

Though SPC has effectively been used in western industries since 1980, […]

Why should you do an FMEA?

Failure Modes and Effects Analysis (FMEA) helps you to understand your processes in detail. It highlights the risks and develops the counter-measures. Furthermore, FMEA enables knowledge transfer and develops a multi-disciplined team in one step.

Many organizations use FMEA as a step-by-step approach to identifying all possible causes of failure. You […]

Rapid Proto Type Services – Concept Through the Production

The introduction of CNC machines radically changed the manufacturing industry. Curves are as easy to cut as straight lines, complex 3-D structures are relatively easy to produce, and the number of machining steps that required human action have been dramatically reduced. With the increased automation of manufacturing processes with CNC […]