Quality & APQP

NA-Mfg’s – Advanced Product Quality Planning (APQP) is a structured process aimed at ensuring customer satisfaction with new products or processes.

APQP focuses on:

Up-front quality planning

Determining if customers are satisfied by evaluating the output and supporting continual improvement

NA-Mfg principles on Quality Assurance :

Fit for Purpose

First Time Right

“First Time Right” is the mantra for the NA-Mfg APQP team. New Product Development is pursued by using Advanced Product Quality Planning (APQP) techniques, with the involvement of the cross-function team. This brings in the collective wisdom of our core team, and process knowledge and is complimented by the use of cutting-edge technologies.

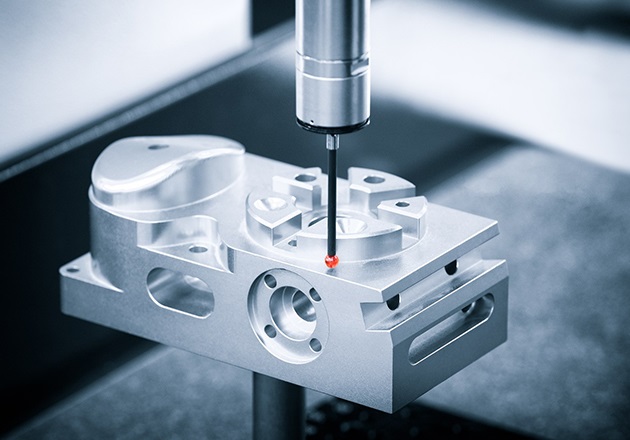

NA-Mfg. uses advanced design software for tool design. Process drawings are made seamlessly and 3D modeling, Mould flow simulations are used for further processing. New Product Development is the core to the growth of NA-Mfg and focuses on New Product Development by Failure Mode and Effect Analysis, and a structured problem-solving approach helped us achieve record-breaking turnaround times. By focusing on the core principles and excellence in engineering.

Focus on process capability at every stage of the manufacturing process and adherence to the NA-Mfg – Quality systems is the key for us to meeting and excelling the stringent quality requirements of our Domestic and International customers.

Our Eco Manufacturing facilities are certified to IATF 16949 and ISO 9001 and AS9000 standards. All of our manufacturing partners are REACH and ROHS compliant.

Core Competence

Innovation

Precision

Proficiency

Intricacy

We have an equally strong team of proficient project engineers, Project Managers, and highly skilled workers, who have helped us grow by leaps and bounds in the last decade. The demonstration of our commitment to providing our customers with their month-on-month requirements has made most of our customers buy more than 15 to 20 products right within the first year of beginning a relationship. We are an efficient, effective, state-of-the-art organization capable of delivering the needs of our customers at cost-effective prices.

Along with our own cutting-edge innovative tools for operational management, we also foster contemporary digital and cloud technologies, and our process & data integrity are benchmarked with the best international manufacturing practices. While making thousands of different castings every year, we measure our success with two goals: Quality of our product & Customer Satisfaction.

Design

We start with a fresh perspective while designing a new product. While designing the prototype, many engineering and setup attributes are involved in tuning each casting to a customer’s requirements, needs and budget.

Our design team follows the following procedures.

- 2D drawings into 3D design models – converting

- Cast Flo Software – Flow Simulation and method validation of parts

- Pre-design casting & machining tools – to shorten the product development lead times