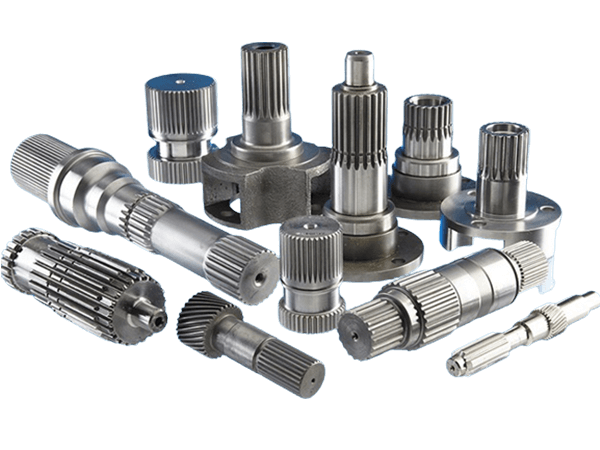

Custom Transmission Shaft

NA-Mfg has an exclusive manufacturing cell to make the Custom designed “Transmission Shafts “ which is used in various Gears boxes and Power transmission equipment. We are equipped with end to the end manufacturing facility, where we can make the Shafts from Ǿ 20.00 mm ( 0.78” ) to Ǿ 200.00mm ( 7.88”) with a maximum length of 2500.00mm ( 98.50” ) Our manufacturing facility consists of world-class CNC machines for Turning, VMC, Cylindrical grinding, By using this facility we can make the custom transmission shafts with the accuracy of +/- 0.005mm ( 0.00019” ) with Ra value 0.4 ( 16.0 Micro inch ) followed by the post process, we have a world-class quality lab to check the Liner and Geometrics dimensions.

Spline Shaft

NA-Mfg has the capability of manufacturing a spline shaft with an outer diameter of 15.00mm ( 0.60”) to 200 ( 7.88” ), and a length of 3.00″ to 60.00″. Module measurements range from 0.5 modules to 12 modules.

shafting manufacturing capabilities include the production of spline shafts for Axles, Power Transmission, Gearboxes, Winches, and other motion control applications. Automated CNC machines give our manufacturing team the versatility to machine the splines. We have extensive experience with meeting the most challenging shape dimensions and tight tolerances.

Spline shafts are designed to have one of two types of splines: internal or external. These types can be used in combinations to transfer torque through a system. There are numerous types of spline shafts, including Involute splines, which have short, curved, and evenly spaced teeth; Parallel splines, which are short, straight-sided splines; serrated splines, which are V-shaped; and helical splines, which are built for optimal load sharing. Each type of spline has its own advantages and disadvantages, involute splines, for example, provide more surface contact for a better transfer of torque, and their design reduces the risk of misalignment with mating pieces.

While spline shafts consist of a single part with grooves cut or rolled into the material, key shafts feature two parts: the shaft with the appropriate keyway, and the key itself. Splined shafts provide a more uniform and controlled transfer of torque.

Most of the Shafts are Q & T and Induction hardened, We ensure the Ultrasonic test in the initial stage, After heat treatment, we check the parts through Magna-Flex ( MPI ) to ensure the parts are free from internal cracks

Involute Spline Shaft

To assure that a spline achieves a proper fit, we request that gaging be included in the budget presented to us. We also recommend full complement gaging for involute splines, especially in difficult-to-reach splines and harder grades of material. The alternative requires measurement between wires / Pins, which frequently is impractical.

For small lot quantities and reverse-engineering solutions where gauging may not be practical, the mating part, either male or female, can be used as the standard. Otherwise, we would have to consider making both parts and researching and developing different possibilities.

Internal Spline Shaft

Shaping and Broaching are two of the most cost-efficient methods to produce the Internal spline Shafts. Maintaining tight tolerances is one of the most critical factors when performing shaping and broaching services. Our manufacturing facility is well-equipped to handle all types of customer-specific requirements.

For shaping, we can cut width from 1/16″ to 3/8″, with a depth of 0.032″ to 0.5″ and a length up to 6″. If the customer chooses our broaching service, we offer a width capacity from 0.063″ up to 1″, with a depth from 0.031″ to 0.5″ and a maximum length of 5″.

Deep Hole Drilled Shafts

NA-Mfg has the capability of making the deep hole drill/gun drill holes for precision transmission shafts which are used in several applications.

Our manufacturing capacity extends to the ranges as,